Dive Compressors

Nitrox

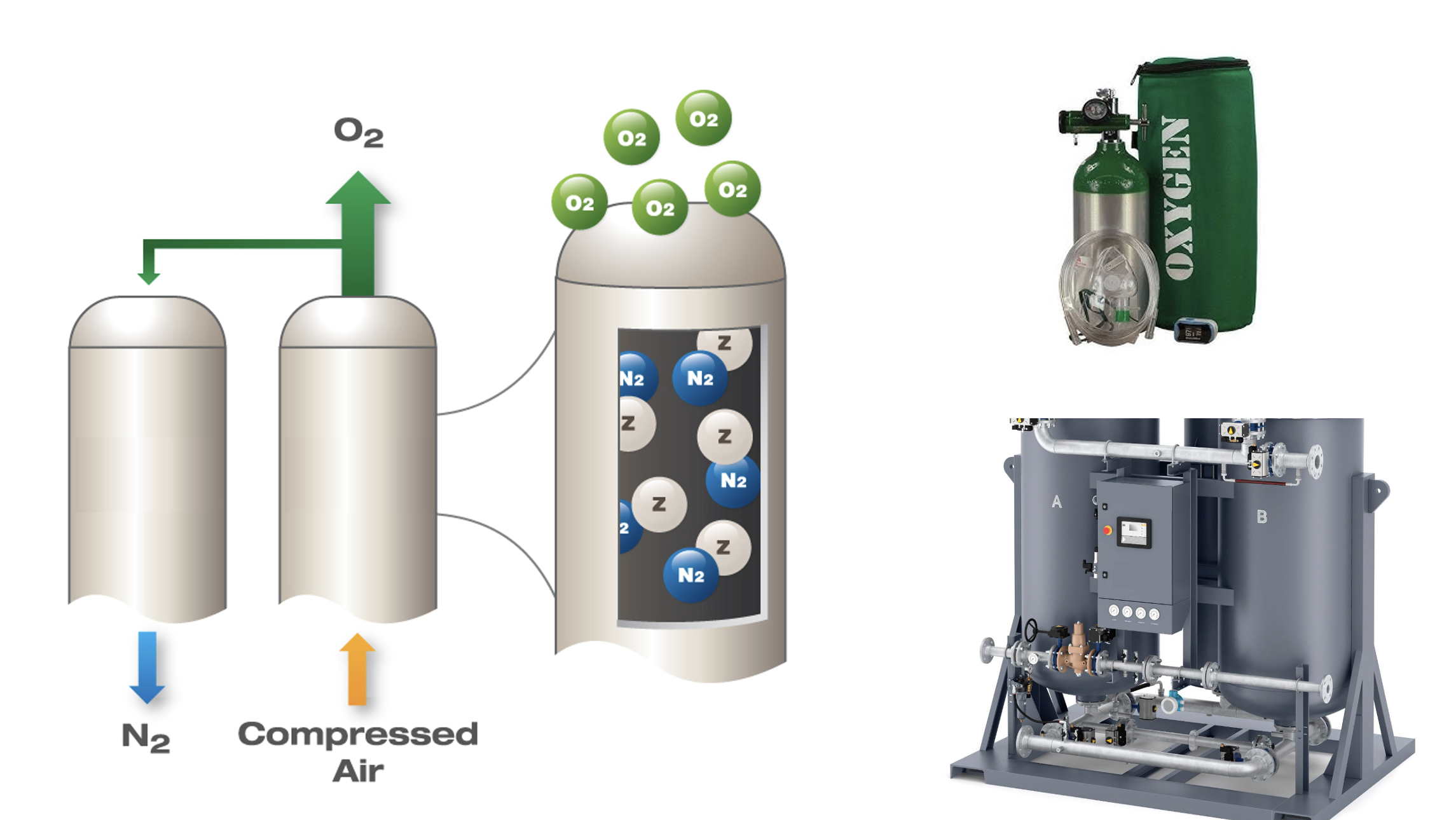

Oxygen Generator

Remote diving operations require planning and availability of O2. When dealing with normo-baric or hyper-baric treatment, O2 consumption requires 30L/min/pp, which may go up to 40-60L under stress/exercise, and unlimited O2 resources becomes the grail.

Storage System

When an application requires constant or sudden high demands for Air, Nitrox, or Oxygen that may exceed the capacity of the compressor’s effective filling quantities, a correctly sized storage system offers many benefits. The purpose of the storage is to serve as a reservoir. It protects compressors from excessive direct demand and serves to dampen or eliminate pressure pulsations to the system.