Many of us love to scuba-dive. It is an activity that is growing day by day in the yachting industry and around the world. Scuba-diving allows owners and crew to experience our magnificent marine wildlife whilst submerged in another dimension.

Scuba-diving is a sport that must be taken seriously, as the descent into deeper water comes hand-in-hand with a change of pressure. For every ten metres we descend, the pressure increases by one atmosphere. Therefore, a good check of our gear before each dive is mandatory, and the ability to equalise whilst descending (adjusting the pressure in our eardrum) is needed to stay safe.

More risks are involved, especially when returning to the surface, as when a diver ascends too rapidly, physiological health issues can come into play. A safe ascend speed is between 9 and 18 metres per minute. When diving, we breathe compressed gas (typically air for the leisure scuba diving industry) which contains 80% Nitrogen. The body absorbs the compressed Nitrogen gas as we go down and the ambient pressure increases. As a certified diver, one should know how to manage the ascent rate, which nowadays is made much easier thanks to more advanced dive computers, which calculate the required decompression stops based on the real-time dive profile. The risk mainly exists in uncontrolled ascents, which can happen due to an ‘out-of-air situation’, a diver’s failure to measure the ascent rate, loss of weight belt, malfunction of the inflation system on a dry-suit or BCD.

During a dive, Nitrogen is absorbed by the body (Boyle’s Law), and the body tissues become saturated with the gas. When a diver ascends too quickly, the nitrogen gas in the tissues will come out of solution and expand at such a rate that the body is unable to eliminate it efficiently, and the nitrogen will form small bubbles inside the tissues. This is known as decompression illness (DCI), commonly called ‘The Bends’, which can be very painful and lead to tissue death or may even be life-threatening. DCI encompasses decompression sickness (DCS) and arterial gas embolism (AGE). For the second one, small ruptures in the lungs can be caused, leading these tiny bubbles to enter the arterial circulation, travel through the body, and eventually lodge in blood vessels and block blood flow. The risk of permanent physical or neurological deficit could affect the future livelihood of the diver and their quality of life.

What this means for the captain and crew on board, especially when sailing in remote areas, is that time is ticking. The priority remains in keeping the patient stable and hydrated whilst providing O2 until evacuation to the nearest decompression chamber is arranged. However, the question marks are too many – if there is a nearby recompression chamber, if it is working safely and being operated by trained personnel, and if evacuation is possible at a low altitude.

Hyperbaric Oxygen Therapy (HBOT) has a proven track record for treating DCS and AGE, which is provided using a recompression (or hyperbaric) chamber. What a recompression chamber allows us to do, in simple words, is to bring the diver back under pressure and, when at the treatment depth, provide pure oxygen for an extended period by following a treatment table.

Recompression chambers have been part of the Navy – and Research – vessels for decades and are usually large metallic structures stored inside bulky twenty-foot containers. Several larger yachts worldwide incorporate one of these large, fixed metallic chambers on board. However, due to size, space, fixed facility regulations and weight restrictions, this is not usually preferable for most yachts, where space comes at a premium.

In 2020, dob opens the conversation on effectively incorporating the professional portable recompression chambers developed for the superyacht industry. We addressed space, design, and crew training, to enable a realistic approach when discussing the feature onboard yachts.

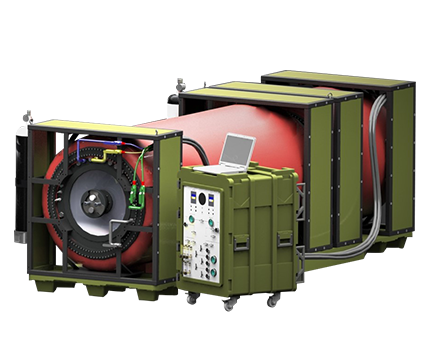

A crucial point for yachts is that the proposed solutions need to respond to the scarcity of space onboard. Especially in the last decade, as yachts are increasingly interested in incorporating diving activities onboard, space is an issue to be addressed. If we talk about submersibles, rebreathing diving facilities, Nitrox compressors, or other dive-related activities, the compromise of space onboard is part of negotiations for acquiring the right equipment and machinery. The proposed hyperbaric solution came in the format of portable and un-foldable recompression systems, which responded to the needs in yachting, and we were interested.

The transportable hyperbaric stretcher weights 50 kg and takes 225 cm of space when deployed. It allows one person to receive on-scene treatment or treatment whilst evacuating to the nearest medical facility. The model is quickly deployed within 15 minutes and is packed into 3 or 4 carriable storage cases when not in use.

The two larger models, which are also compact modular designs, can be unfolded when required. These are not designed to be used as a hyperbaric stretcher but provide multiple occupants allowing two divers to be treated simultaneously, or a diver can be treated whilst receiving hands-on medical support from a second occupant inside the chamber. The foldable model measures only one by three metres when deployed and is just over 1,2 m² when containerised (about the size of a standard pallet), in addition to a control unit and lightweight, portable gas tanks. The modular model is equipped with a second lock, allowing a medical professional to move in and out of the chamber during treatment. The equipment is designed for rapid deployment, an additional luxury when the drill becomes a reality.

With thirty years of experience, the factory, not only proved to have adequately tested their equipment but also sold their solutions to the defence sector, rescue services, and other professional applications. The equipment is ISO certified as a Medical Device, Lloyds Registered witnessed tested and meets the requirements of ASME-PVHO, the world’s leading safety standard for Pressure Vessels for Human Occupancy. Their untarnished safety record has made their range of Chambers the system of choice when it comes to the United States Navy, which features the hyperbaric stretcher in the US Navy Diving Manual (Revision 7) and has supported the development of the new Multi-Occupant Flexible Recompression Chamber System (MOFRC), a 6 ATA Systems for their diving operations. So we felt safe and time to shake hands on a collaboration as representatives was at the order of the day.

As looks are important for the design of yachts, we continued the discussion to find the proper setup for them. Through the assistance of shipyards, suitable solutions to integrate the equipment without interfering with the design were available when looking at incorporating the two larger models. In addition, technical advisors provide innovative – and suitable – solutions to unfold the equipment when needed and be unseen when stored.

We could not find any reason why the yachting sector could not use these technologies when training their crew. Training is part of the job as seafarers, and an onboard hyperbaric operational and technical course has been set up. Depending on the crew’s level of knowledge, the course can take from five to seven days and covers medical procedures and technical maintenance. In addition, a yearly audit to certify the equipment is in place to serve the purpose of a safe hyperbaric operation on board. A Swap-In Swap-Out service for yachts operational all year round has been developed.

As a testimonial, public speaker and BBC presenter Paul Rose, also known for being the expedition leader during the National Geographics ‘Pristine Seas’ project, will be providing us with his experience using the Transportable Hyperbaric System in a small video that will be featured on our webpage soon.

Stay safe

Capt. Dominique Geysen

Photo Credit and Special thanks to: Damian Pessano